Conveyor Chains

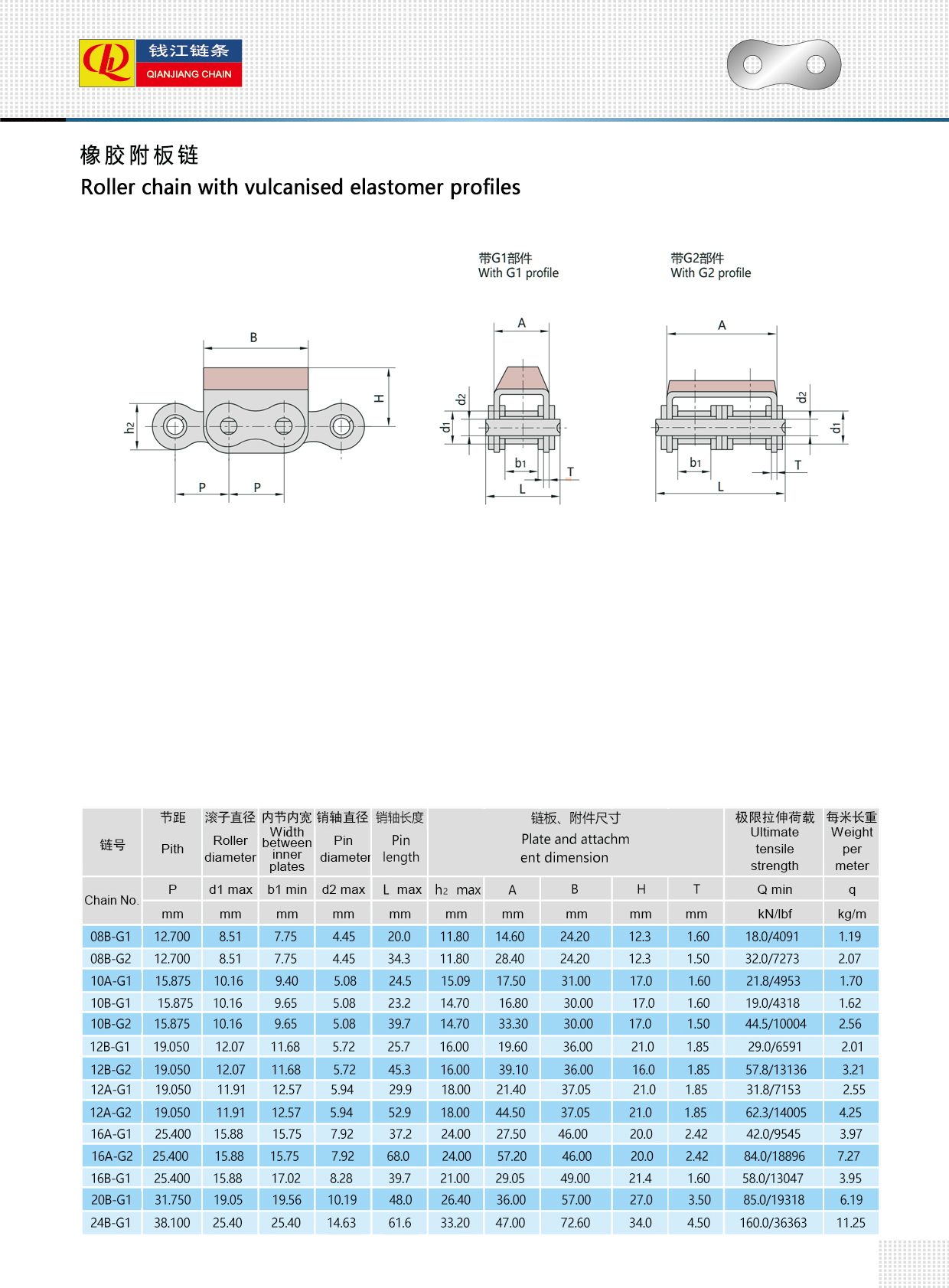

Roller chain with vulcanised elastomer profiles

In modern industrial automation production, the stability and efficiency of the material conveying system directly affect the overall production capacity and quality. As a high-performance integrated transmission and conveying solution, the Roller chain with vulcanised elastomer profiles is widely used in food processing, logistics sorting, agricultural machinery, packaging equipment and other fields, and stands out for its wear resistance, shock absorption and anti-slip properties. The Roller chain with vulcanised elastomer profiles is based on the standard roller chain, and uses an advanced vulcanization process to firmly bond high-quality rubber or thermoplastic elastomer to the outer chain plate or bearing plate of the chain. This composite structure not only retains the high strength and durability of the metal chain, but also gives it the following unique advantages:

High friction surface: prevents material slippage, especially suitable for inclined or high-speed conveying.

Shock absorption and noise reduction: effectively absorbs vibration and noise during operation, and improves the comfort of the working environment.

Wear resistance and corrosion resistance: the rubber layer protects metal parts from wear and chemical erosion, extending the service life.

Cleanliness and hygiene: suitable for industries with high cleanliness requirements such as food and medicine.

Download PDF

Download PDF

浙公网安备33010902004043号

浙公网安备33010902004043号