Submit feedback

Stable Chain Manufacturer

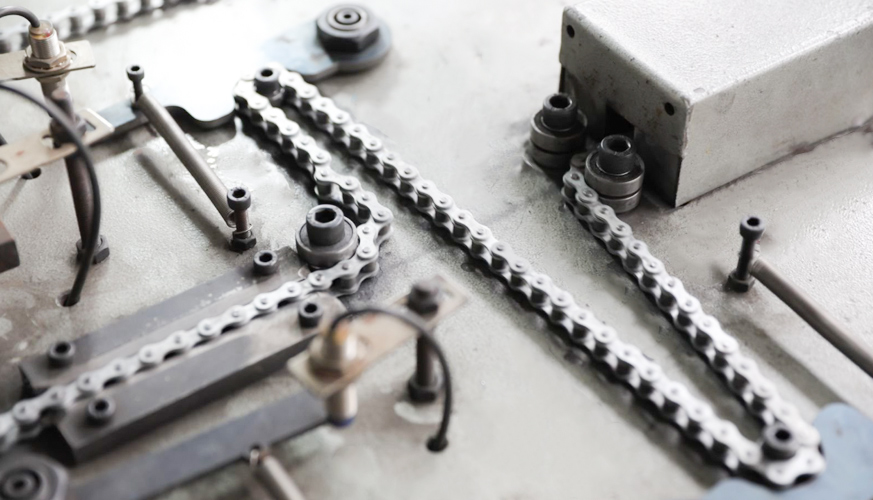

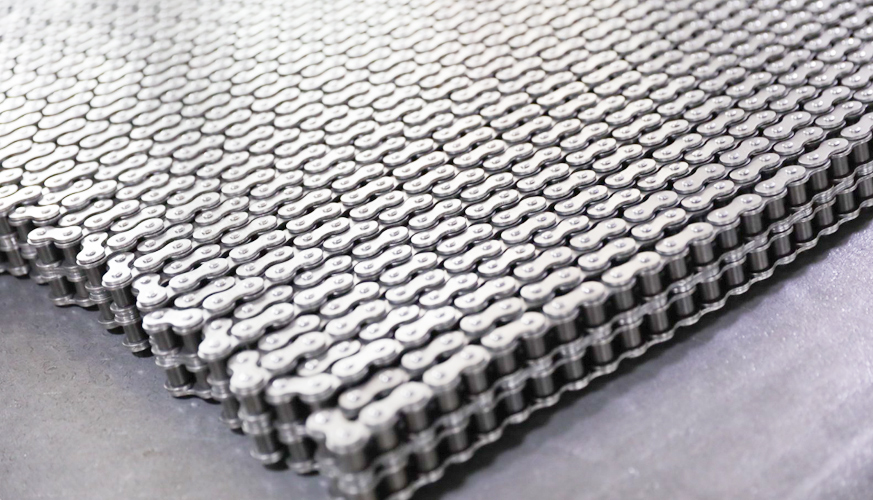

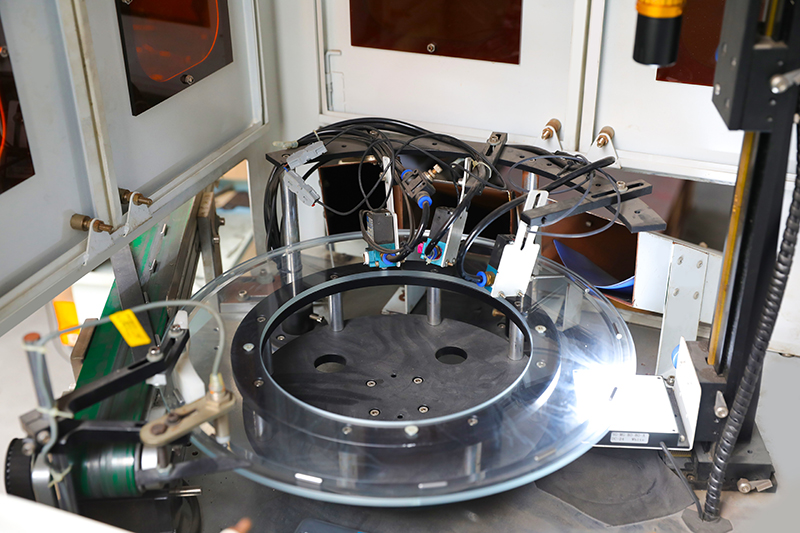

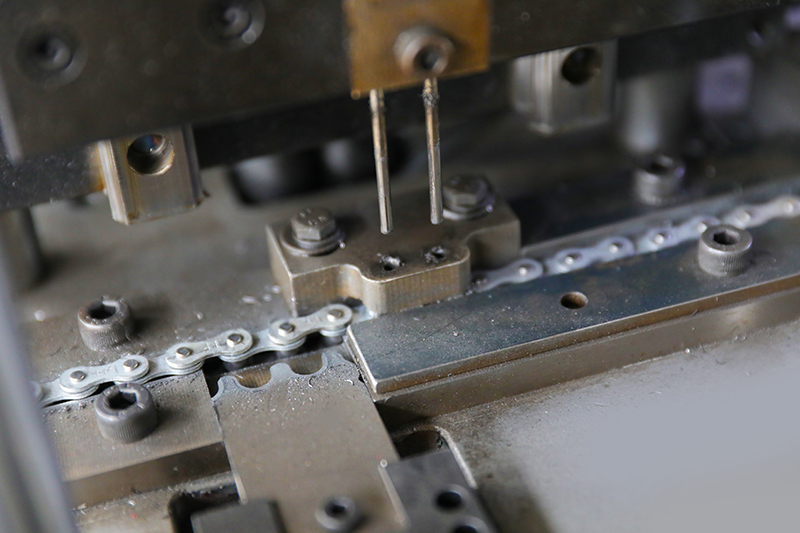

Our company has established a complete quality management system and production "ERP" system application, and is equipped with advanced digital testing equipment. Introduce automatic visual inspection equipment for all parts to achieve inspection.

Technical Support

Assembly Inspection

· Check whether the circlips, cotter pins, etc. at the chain joint are installed correctly.

· Check that the cotter pin at the chain joint is deployed correctly.

· Check for proper tension (not too loose or too tight).

· Check if the chain is touching the chain cover.

· Check that the chain is properly lubricated.

Daily Inspection

· Check for abnormal vibration, noise, etc.

· Check for obstructions that may interfere with the chain and sprockets.

· Check chain components, dirt, corrosion, improper lubrication, etc.

· Check each component for scratches, deformation, damage or other abnormalities.

· Check the roller rotation, bending or clearance of various parts.

· Check the condition of the contact area with the sprocket.

· Check chain wear elongation.

· Check whether the joint, circlip or cotter pin is abnormal.

· Check the chain for rust (red rust due to poor lubrication or rust due to environmental deterioration).

· Check for carbonization or other deterioration of the lubricating oil.

· Check for sticky powder or forgings that accelerate wear.

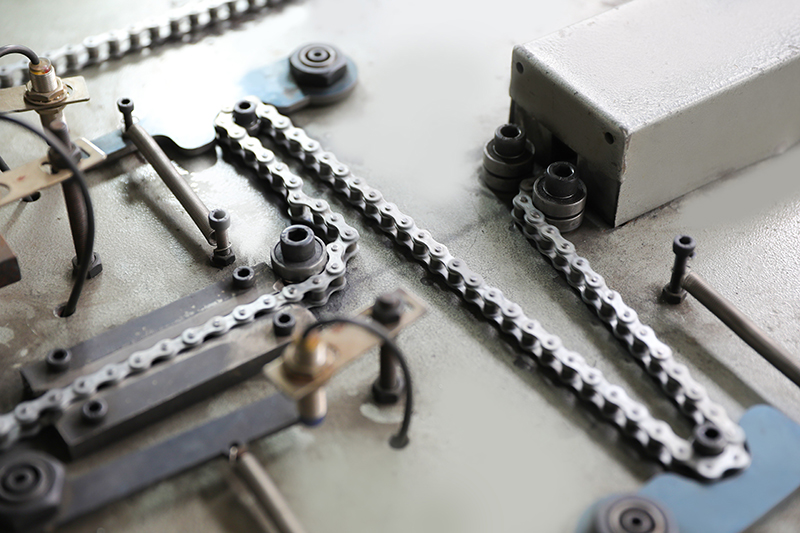

Periodic Inspection

· Check paragraphs (1) and (2) above visually or using a measuring device with the machine running, stopped and with the chain removed.

· Check regularly according to usage conditions and environment. If the usage conditions are severe, the number of inspections should be increased.

浙公网安备33010902004043号

浙公网安备33010902004043号