Submit feedback

High-Strength Plate Chains for Rock Bolt Drilling Machinery

Posted by Admin

The newly developed high-strength plate chain alloy steel chain for rock bolt drilling rigs by Qianjiang Chain is designed for two core functions: power transmission and actuation drive.

With a strong focus on high adaptability, stable torque output, and compatibility with electrification, it has become one of the core transmission solutions for electric rock bolt drilling rigs.

The specific applications and characteristics are as follows:

I. Core Application Scenarios

Focused on Key Operating Stages of Rock Bolt Drilling Rigs

1. Drilling Power Transmission

The chain is applied to the drill boom drive and main spindle drilling system of electric rock bolt drilling rigs. It converts the high-speed, low-torque output of electric motors into reduced-speed, increased torque transmission through chain drive, delivering drilling torque suitable for both hard rock and soft rock formations.

It is particularly suitable for medium and heavy-duty electric drilling rigs operating under high-torque working conditions.

2. Drill Boom Position and Attitude Adjustment

The chain is used for lifting, swing angle adjustment, and telescopic movement of multi-boom drilling rigs.

With a constant transmission ratio, chain drive enables precise control of drill boom positioning, ensuring drilling verticality, which is a critical requirement for rock bolt support.

This supports multi-boom coordinated operation and meets the accuracy requirements of intelligent anchoring systems.

3. Rock Bolt Conveying and Installation

Integrated into the rock drilling and bolting combined machine, the chain-driven pushing mechanism enables smooth and stable rock bolt feeding.

After drilling, it cooperates with rapid anchoring operations, reducing process intervals and supporting one-button drill-and-bolt workflows, significantly improving support efficiency.

4. Auxiliary Mechanism Drive

The chain is also applied to hole cleaning devices and support accessory conveying mechanisms.

Its simple transmission structure and low failure rate make it suitable for continuous operation in harsh environments such as underground mines and tunnels.

II. Key Advantages for Electric Rock Bolt Drilling Rigs

1. Strong Transmission Compatibility

The chain transmission perfectly matches the power characteristics of electric motors, achieving direct speed reduction and torque amplification without complex intermediate transmission components.

Its compact structure allows easy integration into the limited installation space of drilling rigs.

2. High Stability and Durability

Chain drive features no slippage and accurate transmission ratios, with strong resistance to impact loads.

It effectively handles sudden changes in rock hardness and drilling jamming impacts, making it suitable for mining and tunneling environments with demanding operating conditions.

3. Alignment with Electrification Trends

With a simple structure and convenient maintenance, the chain drive avoids oil leakage associated with hydraulic systems and noise issues common in pneumatic systems.

It meets the requirements of zero-emission, low-noise, and environmentally friendly operation, making it well suited for urban tunneling, foundation pits, and other green construction scenarios.

4. Easy Integration with Intelligent Systems

The chain transmission system can be combined with torque sensors and speed encoders to collect real-time transmission data.

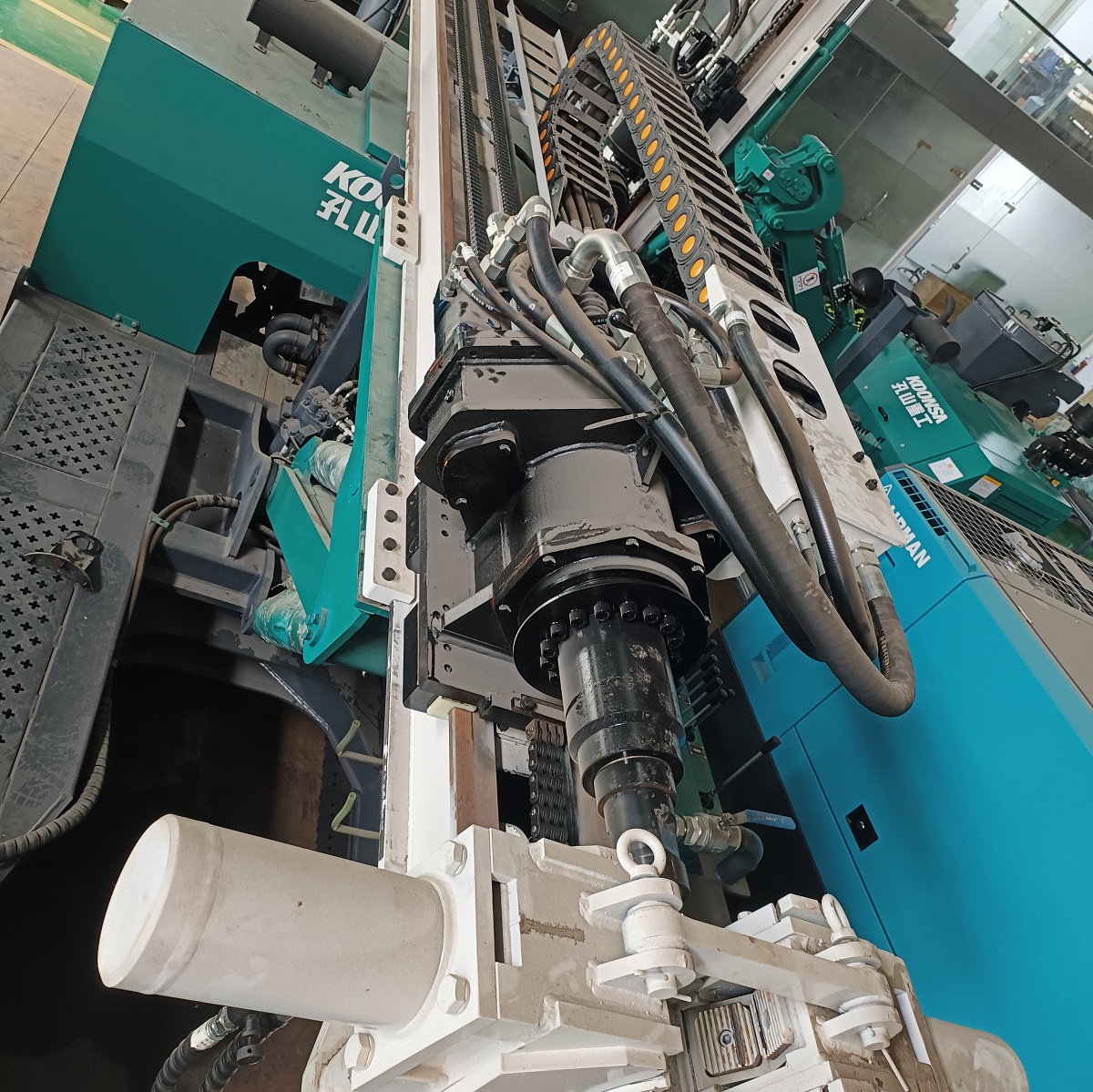

This data can be fed back to AI control systems to enable adaptive drilling parameter adjustment and fault early warning, supporting the perception and decision-making requirements of intelligent rock bolt drilling rigs (equipment photos attached).

III. Application Limitations and Optimization Directions

Based on Practical Operating Conditions

1. Limitations

At high operating speeds, slight vibration may occur, placing higher requirements on chain lubrication and tensioning systems.

In dust-intensive underground environments, protective dust covers are required to prevent accelerated chain wear.

2. Optimization Measures

Current solutions mainly adopt wear-resistant alloy steel chains combined with automatic tensioning and intelligent lubrication systems, together with sealed dust-proof structures.

These measures extend chain service life from approximately 2,000 hours to over 5,000 hours, making them suitable for long-duration continuous operation.

-

I. Introduction Conveyor systems form the backbone of modern industrial automation, enabling the eff...

READ MORE -

1. Introduction 1.1 Definition and Basic Concept of Coupling Chains Coupling chains are mechanical d...

READ MORE -

1. Introduction to Leaf Chains Leaf chains are a type of mechanical chain used in a variety of indus...

READ MORE

浙公网安备33010902004043号

浙公网安备33010902004043号